Focused on pneumatic components for 15 years

Customize your pneumatic equipments

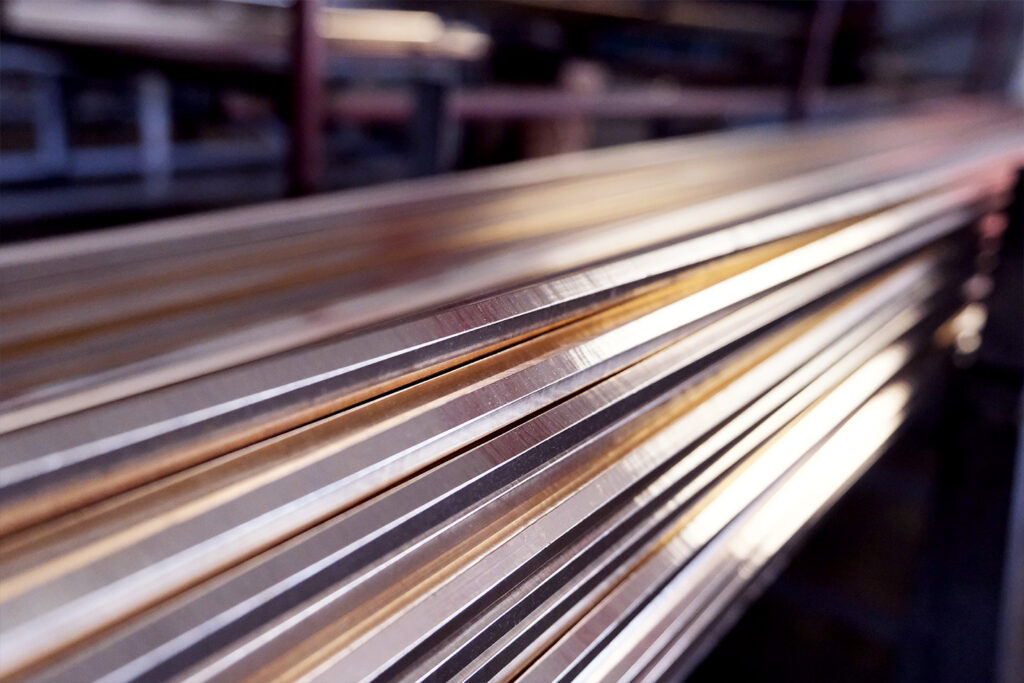

Adopting international standard processes, carefully selecting high-quality materials, ensuring long equipment life, low energy consumption, and meeting the demands of harsh industrial environments.

Affordable Prices

Automated machine production, low labor cost and high precision

Expert Team

We are an integrated R&D, production and sales manufacturing factory equipped with our own professional foreign trade department.

Quality Assurance

We are an ISO 9001-certified factory with strict management. Our products have CE, RoHS and other certifications.

Customized Service

We provide professional customized product services to meet your requirements.

OUR COMPANY

Zhejiang Xuanao Pneumatic Technology Co., Ltd. was founded in 2011 and is a technology-based enterprise specializing in the production of pneumatic components.

Established with a focus on innovation and quality, the company primarily manufactures products such as quick-connect pneumatic fittings, throttle valves, and quick-twist couplings, while also offering custom processing services based on client-provided designs or samples.

OUR CERTIFICATIONS

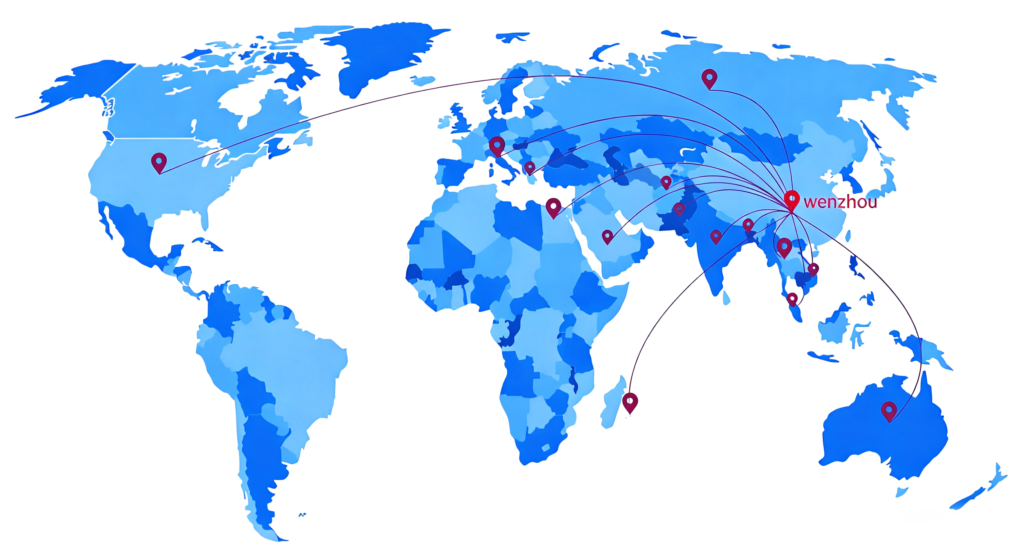

BUSSINESS OVER THE WORLD

OVER 500+ Big Customer

We are a professional original manufacturer of pneumatic components, with a global product sales network that has covered many markets including the United States, Australia, China, Turkey, India, Iran, Colombia, Thailand, Vietnam, Bangladesh, Indonesia, South Africa and more…

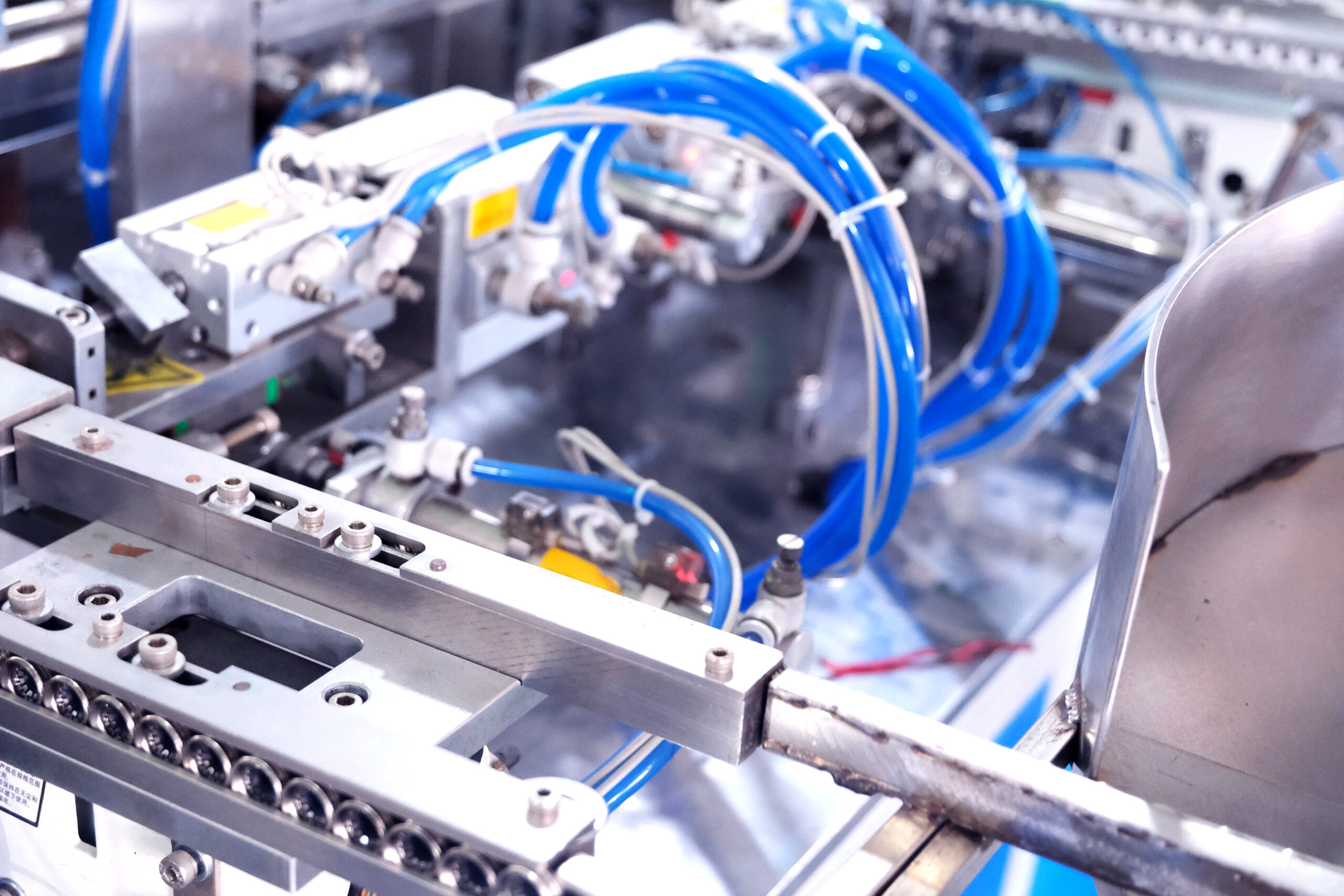

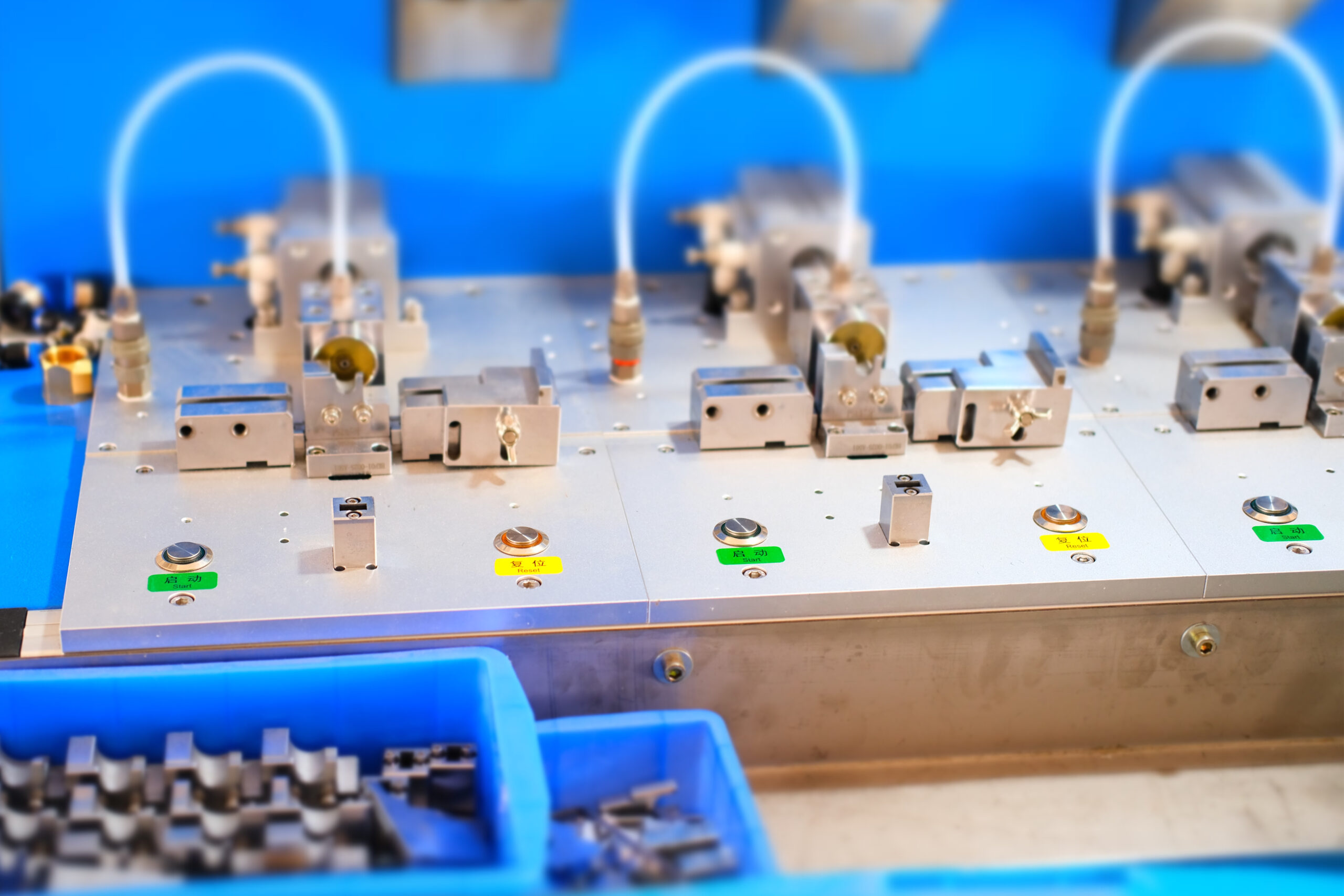

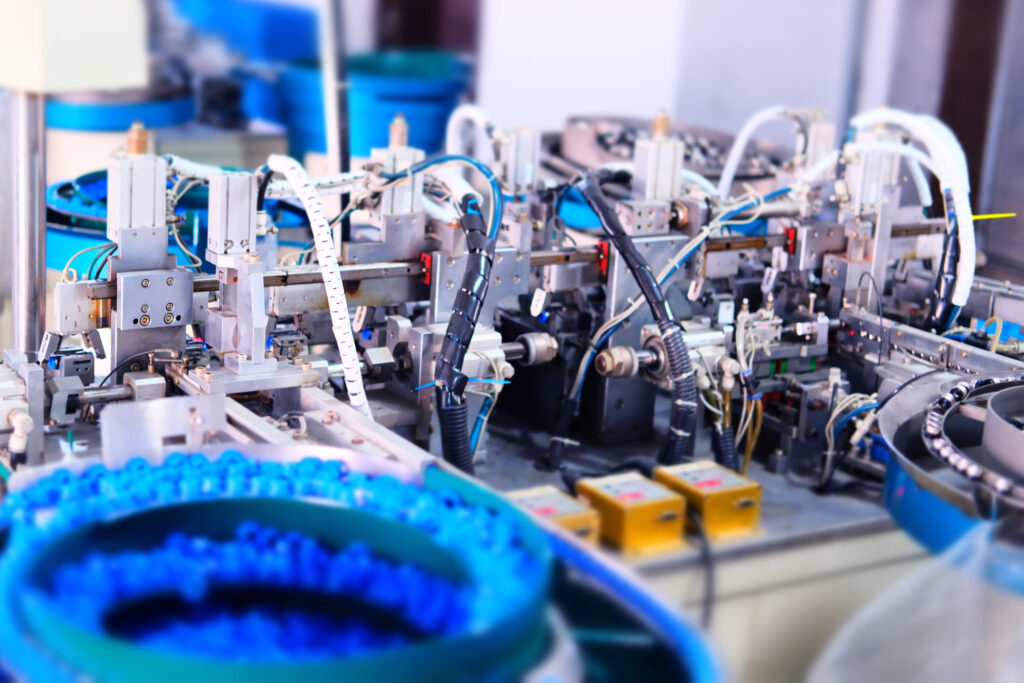

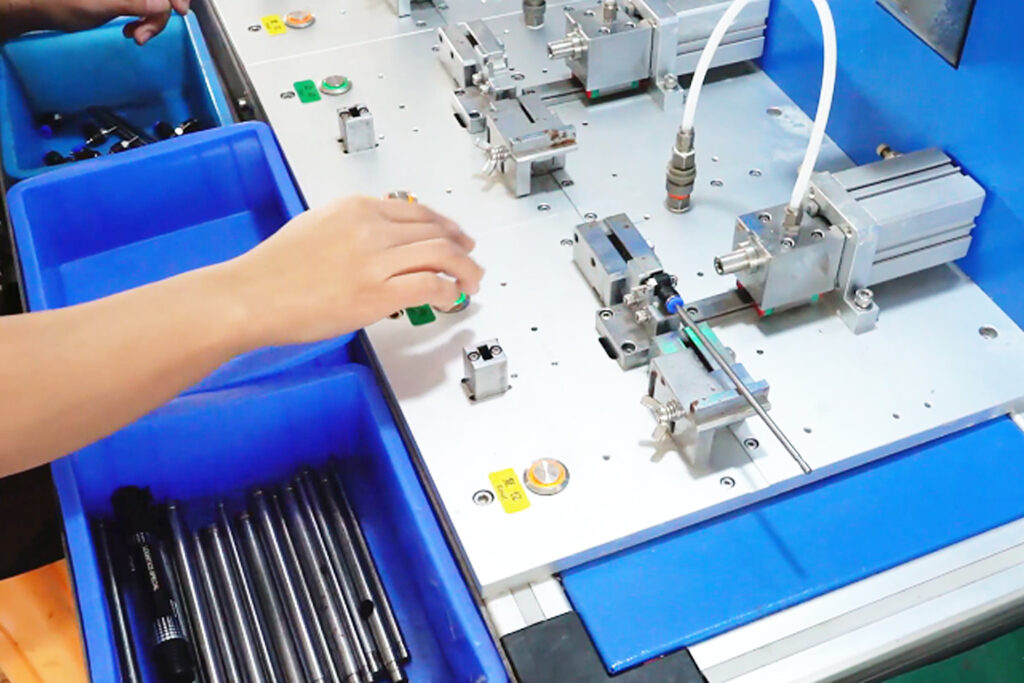

FACTORY WORKSHOP

10000+ m3

200000PCS/DAY

200+ MACHINES

80+EMPLOYEES

Our factory covers an area of over 10,000 square meters and has an integrated team responsible for design, R&D, production and sales. It is equipped with more than 200 sets of advanced automated equipment and has a workforce of 80 employees. Over 95% of its products are manufactured by automated equipment, with a full-load daily output of 200,000 pieces.

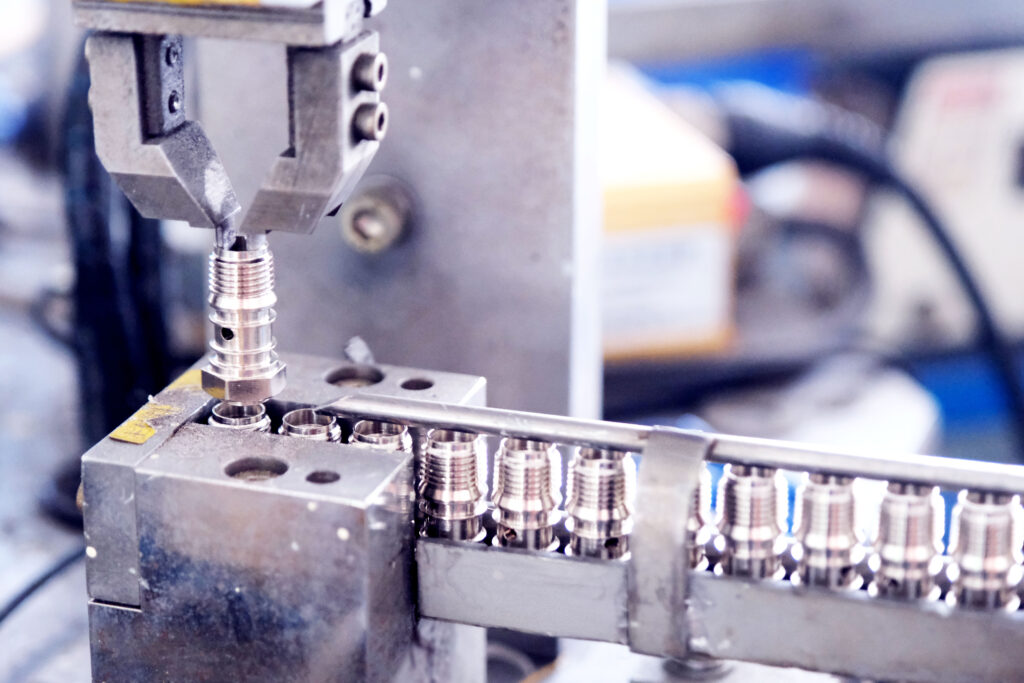

PRODUCTION PROCESSION

Raw Material Selection and Pretreatment

Precision Molding and Processing

Injection Molding

Dried plastic pellets are fed into an injection molding machine, heated and melted, then injected into a mold. After cooling and solidification, the product is demolded. The precision of the mold directly determines the dimensional consistency of the joint.

Surface Enhancement Treatment

Automated Assembly and Integration

Comprehensive Quality Inspection

Standardized Packaging and Warehousing

FAQs About Pneumatic Components Wholesale

Can I come to China for factory inspection?

Are you a manufacturer or a trading company?

We are a manufacturing company specialized in pneumatics field for over 15 years.

Are OEM and ODM services available?

Yes, just simply provide your drawing and your requirements.

Can you provide samples? Are samples free?

Yes, we can provide samples. Normally,we provide 3-5 pcs free samples for test or quality checking.

But you have to pay for the shipping cost.

How long does it usually take for me to receive the goods?

For products in stock, we can send the stock products in 3 workdays. If without stock , or stock is not enough, we will check the delivery time with you.

Can I become an Agent / Dealer ?

Welcome ! But please let me know your Country/Area first, we will have a check and then talk about this.

If you want any other kind of cooperation, do not hesitate to contact us.

Are there any requirements for MOQ?

Yes, for normal products, our MOQ is 100 pcs.

But for special items, let’s discuss the MOQ based on real situation.

How about warranty?

The warranty time is one year. We can repair or change because of the quality problem.

Ready to collaborate with us?

Send us a message if you have any questions or request a quote.